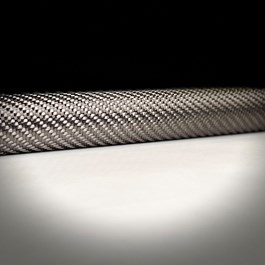

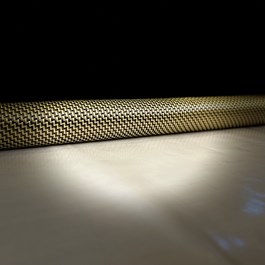

Our production processes and equipment are designed for a prepreg width of max. 1,300mm and an area weight between 50 to 1 300 g/m².

We have the possibility of double-sided impregnation for heavy or difficult-to-impregnate fabrics, which enables us to achieve exceptional mechanical properties and an optimized level of impregnation.

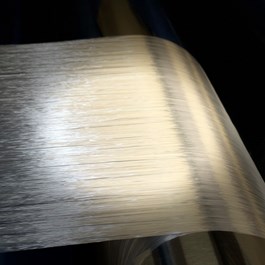

In addition to our standard widths for fabric prepregs, we are able to configure your UD tapes to your requirements regarding width with our online cutting system.

Our online, permanent x-ray measurement system guarantees you an exact resin weight or percentage on the entire prepreg width.

We are ISO certified and we have implemented robust internal quality ensurance and traceability system.

Please contact our Sales Team to learn about standard items we hold on stock for short term deliveries:

We manufacture on customer orders and requirements:

We also offer:

Nylon and polyester based

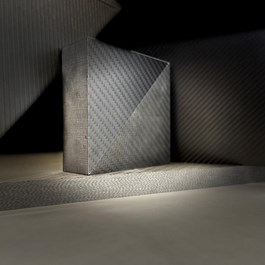

Dimensions: 600 x 800 mm

Thickness up to 65 mm

Carbon/Aramide

(1) Recommended process pressure to reach optimal part quality is 5-7 bar. EP1NT is developed also for applications that cannot be cured in an autoclave.

(2) Tg values are from DSC (Polyma DSC214, 20 °C/min)

(3) Polyma DSC214 modulus tangent interception, 5 °C/min

(4) Recommended curing cycle. An alternative curing cycle could be used and may be required. This depends on the used process, curing temperature, used tool material and the thickness of the end product.

* System can be adopted to specific customer production processes and part design.